Rotating the World Sustainably & Reliably with TECO’s Solutions

Electric motors convert electrical energy into mechanical motion, but the way they use electrical energy differs significantly. The two broad categories, Alternating Current (AC) and Direct Current (DC), use different power supplies, construction principles and control methods. Understanding these differences is essential before selecting a motor that is technically suitable and compliant for your application.

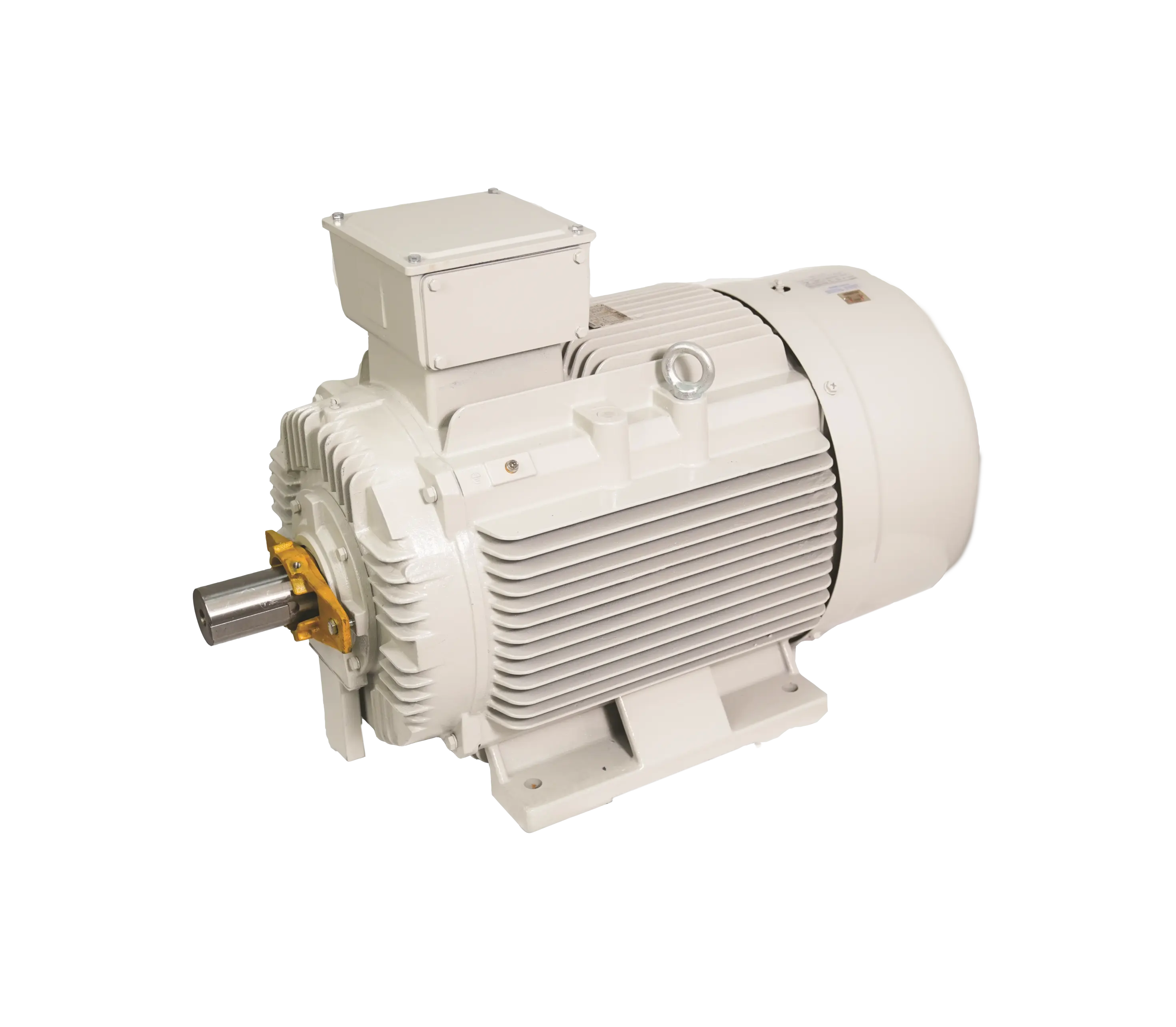

At TECO, we bring more than 50 years of experience supplying motors engineered for industrial reliability across Australia and New Zealand. Our range covers motors used in Mining, Oil and Gas, Coal, Agriculture, Power and Energy, Food and Beverage, Water Infrastructure and Hard-Rock Mining, supported by local stock across 6 branches in Australia and New Zealand and TECO ModShop capability.

So, what makes AC and DC motors different? Let’s take a detailed look.

AC motors use alternating current to produce a rotating magnetic field in the stator. In the most common design—the squirrel cage induction motor—this rotating field induces current in the rotor bars, producing torque. Torque is generated by the interaction between the induced rotor currents and the stator magnetic field, with the rotor operating at a small slip relative to synchronous speed.

AC motors used in Australian and New Zealand industry are typically IEC 60034 / AS-NZS compliant induction motors, available in IE2, IE3 and IE4 efficiency classes. Their construction is brushless, mechanically robust and suited to continuous-duty applications such as pumps, fans, compressor motors, conveyors and general industrial drives.

In VSD (Variable Speed Drive) applications, AC induction motors offer stable operation across a wide speed range without requiring brushes or commutation maintenance.

Variable Speed Drives (VSDs) enable precise management of motor speed and torque while improving system energy efficiency. AC induction motors paired with VSD control are now the dominant approach in industrial pumping, HVAC, conveyors and process control across Australia and New Zealand.

TECO motors use Class H insulation systems with temperature-rise limits tuned to AS/NZS and IEC 60034 requirements. Mining-duty and water-industry variants are available up to IP66, ensuring long service life in abrasive, wet or corrosive environments.

TECO AC motors are widely applied to pumps, compressors, conveyors, fans and agitators, where reliability, efficiency and long-term mechanical stability are essential.

DC motors use direct current and rely on either mechanical commutation (brushed DC motors) or electronic commutation (brushless DC motors). Brushed designs use a commutator and brushes to switch current direction in the armature; this introduces wear and requires periodic inspection. Brushless DC motors avoid this limitation using electronic switching.

Motor speed is determined by the armature voltage and field flux. Modern DC drives employ chopper or PWM control for precise speed regulation. DC motors are commonly used where battery supply is required or where specific torque characteristics suit small machinery, vehicles or specialised automation.

It is important to note that wound-rotor motors are AC induction motors, not DC motors. They are used where high starting torque or variable slip characteristics are necessary.

DC motor speed is regulated through armature voltage variation or PWM (Pulse Width Modulation), providing linear torque characteristics across a broad speed range. Field weakening can be applied for extended speed capability in wound-field machines.

Brushed DC motors require routine inspection involving brush wear checks, commutator cleaning, lubrication of bearings and field-coil condition assessment. These factors must be included in the planned maintenance schedule, especially in high-duty environments.

DC motors continue to serve specific roles in traction drives, battery-powered systems, cranes, hoists and specialised process equipment demanding tight speed regulation and rapid torque response.

So, AC and DC motors operate differently and are applied for different applications, but what are the key differences that set them apart?

Identifying these differences is essential in helping you choose the right motor for your application. It’s not a question of better or worse, but which is right for you.

When specifying motors for critical infrastructure or process plants, evaluation should include:

The appropriate motor depends on power supply, duty cycle, environmental conditions and control method. DC motors are used for battery-powered systems or specific torque characteristics. For most industrial applications in Australia and New Zealand—particularly pumping, HVAC, conveyors, compressors and mining—AC induction motors are the most robust and cost-effective choice, offering long-term reliability and compatibility with any VFD brand.

TECO’s range includes IE3 and IE4 TECO Squirrel Cage induction motors, designed as drop-in IEC replacements, as well as TECO Wound Rotor AC motors for high-torque heavy-load applications.

Explore your high-quality electrical motor options with TECO, or contact our team for further advice on which motor will work best for your application.

At TECO, we’re committed to providing you with options for your electrical motor demands. With our range, you can explore high-performance motors with industry-leading technology. Choose reliability when you explore our range of electrical motors.

Whether you’re looking for an AC motor or a DC motor or want to explore our other options, we have you covered.

If you’re not sure what you’re looking for, our team can help you get started. Contact us today.